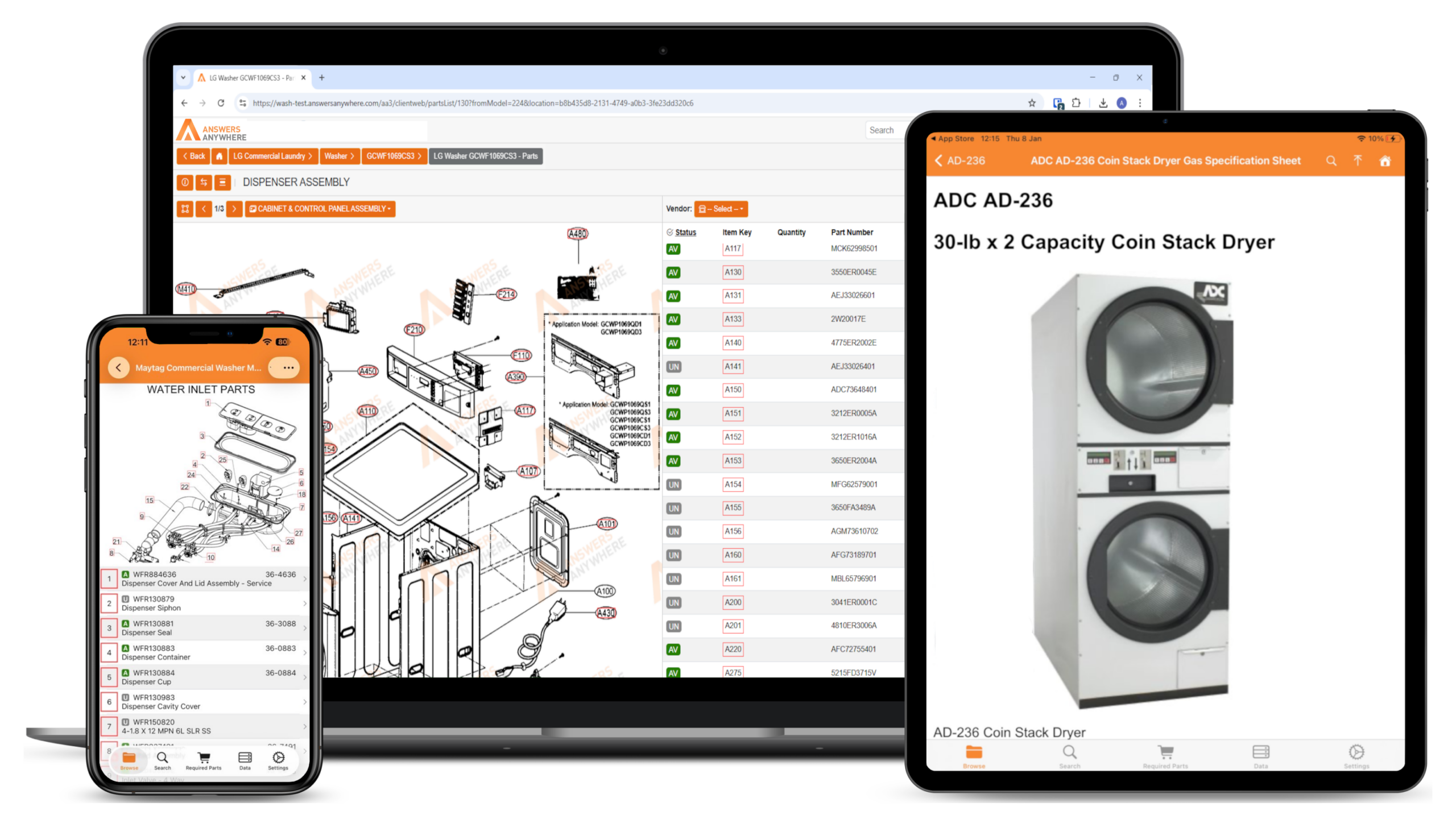

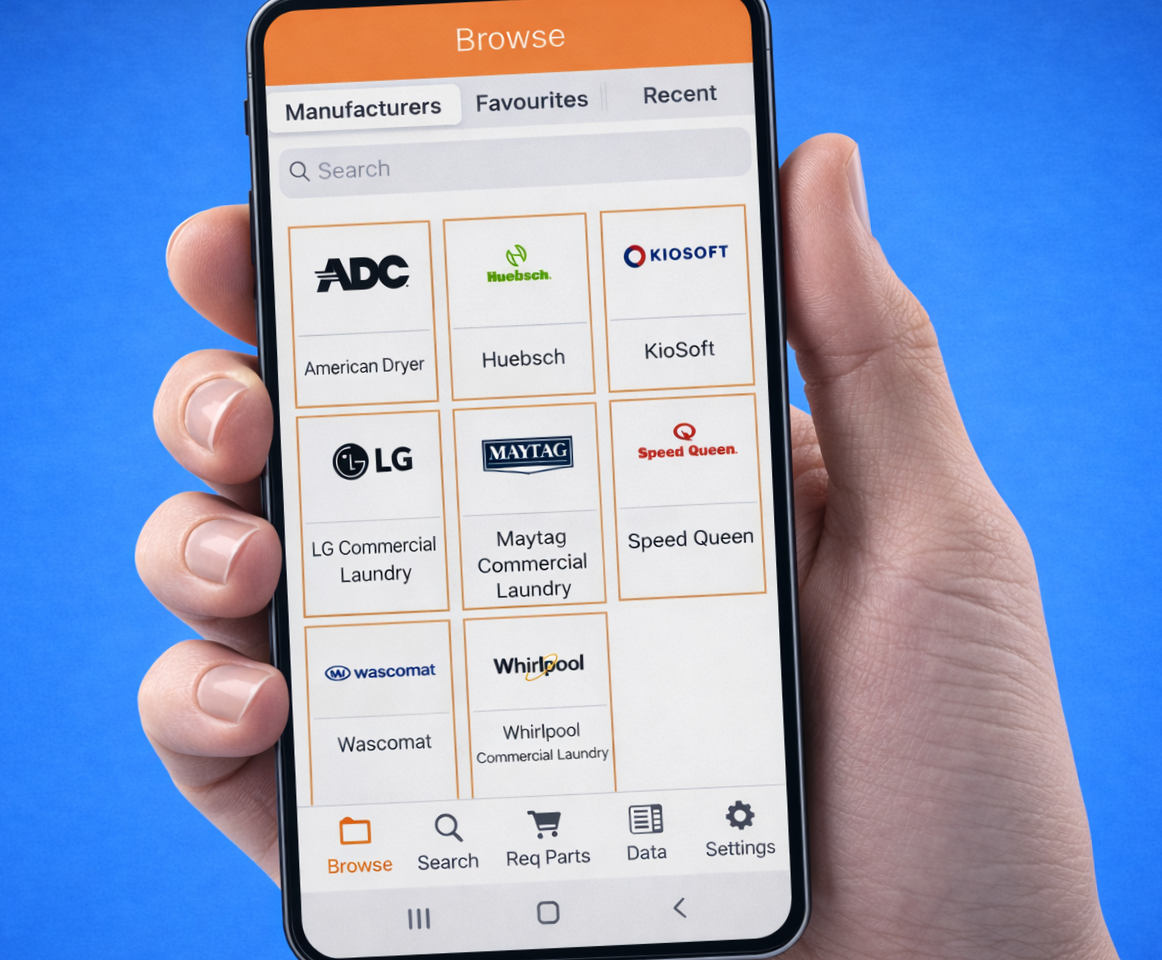

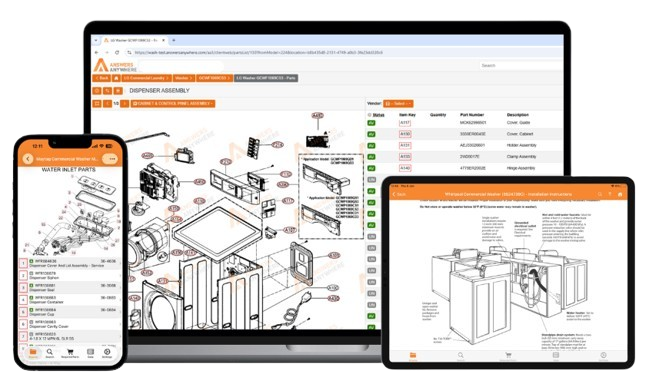

AnswersAnywhere transforms service manuals, parts lists, diagrams, and technical documentation into structured, governed service data. This data is delivered at the point of need through a web or mobile platform.

The purpose of AnswersAnywhere is to put critical equipment data at the centre of every service call, closing the gap in access to technical and parts information when technicians need it most. Equipment data will be:

-

Centralised

-

Structured, interactive and searchable

-

Integrated with field service systems

-

Accessible online and offline

-

Maintained and kept current

By embedding technical parts and service data directly into operational workflows, service organisations standardise execution, reduce variation, and improve financial performance across the service lifecycle.

When technical service data is fragmented, operational performance and overall service cost suffers.

First-time fix depends on accurate parts and technical data — yet this is often the missing link in service workflows. Over time, this fragmentation creates:

-

Inconsistent service execution

-

Margin erosion through repeat visits

-

Increased cost-to-serve

-

Knowledge dependency on individuals

-

Disconnected processes between systems

AnswersAnywhere closes the gap between diagnosis and job completion by embedding the right technical and parts data directly into the core of every service workflow.